TwoTrees Sapphire Plus (SP-5) Review

I’ve been looking at 3D printers for a while now and I finally decided it’s time to get one and see if they are as useful as one may think. In this post I’m going to explain the reasons why I decided that TwoTrees Sapphire Plus was the best choice for me.

TL;DR; Sapphire Plus has a great foundation: the frame is very rigid, all axis run on linear rails and the gantry is very light but it’s a printer that will likely require tinkering with. If you have no experience in 3D printing or little general DIY experience you may want to look at the other contenders below.

Making the choice

I was shopping for a printer fitting the following criteria:

- Large build volume. I had some projects in mind that would require 300x300mm build volume.

- Enclosed or easy to enclose. I wanted to print ABS which likes being printed in enclosed space. Plus, the noise is reduced when printing in an enclosure.

- Affordable. I didn’t want to invest a lot before I figured out how much I would use a 3D printer.

- Fast. I would mostly print functional prototypes so speed was more important than quality.

Based on these requirements, I came up with the following contenders:

At the time when I was making the purchase, all of these cost about the same. They were all affordable and they all had build volume of 300x300mm. However, one printer stood out: TwoTrees Sapphire Plus. It was the only printer in this price range with CoreXY kinematics. In core XY design the printer tool head moves in XY axis and the build platform goes up and down in Z axis. This means that you can print faster since you no longer need to move heavy bed back and forth like on typical cartesian style printers. It also means that the printer is more compact since you don’t need to leave space behind the printer for the bed to rock back and forth. It’s a lot easier to enclose a Core XY printer: their frame already makes a cube without panels. Also because the volume to enclose is smaller it heats up faster.

There were a few areas where Sapphire Plus was lacking:

- Extruder. It came with an older style bowden extruder. It means it’s not suitable to print flexibles, it’s a bit slower and it’s harder to tune. The other printers came with a direct drive extruder. However, it’s an easy to upgrade component and the direct drive setups you get on the other printers were not that great either.

- 24V bed. Artillery Sidewinder X1 comes with AC bed which heats up a lot faster. However all beds that come on cheap 3D printers from factory are somewhat questionable quality. They’re usually not very flat from the box or warps soon after heating them up.

- Reviews and the manufacturer. This was the biggest one: TwoTrees has questionable quality while the other two come from a lot more reputable companies. They also have bigger comunity so you have a lot more choices when it comes to after market upgrades. I’ve also read a lot of comments about quality issues, lack of support and problems with the firmware.

Despite the downsides and harsh reviews I decided to go with Sapphire Plus. After all, the issues can be fixed/improved while you cannot convert cartesian printer to Core XY without a complete redesign.

How is it?

Sapphire Plus came as a kit and required quite a lot of assembly. The manual is poorly written and makes the process rather difficult for a fist timer. The first prints came out great and I didn’t have the issues I’ve heard from other people:

- MK8 style hotend is not bad at all. I didn’t have clogging issues and I think those who do probably assemble it wrong: you have to make sure to cut the PTFE tube very straight and sit it right to the nozzle. However it’s a PTFE lined hotend so you should not print over 250C with it. I got the Dragon hotend for PETG/ABS printing but I kept MK8 for PLA printing. If you are going to print only PLA you might not even need to change it.

- The bed was flat enough that I didn’t have any 1st layer adhesion problems. I was concerned about it warping so I configured it to run at 80% max power. It’s a bit slow to heat up for ABS printing but I still use it to this day (it reaches 80 in 6 minutes, but going from 80 to 100 takes another 6 minutes). Even the cheap build plate sticker that comes with it has served me well. Prints were adhering even too much and I had to use glue stick to help getting them off. Eventually I ripped a piece of it with a stuck PETG print and replaced it with IKEA “LOTS” mirror tile.

- The bowden setup worked well for PLA prints but when I started PETG printing I got a lot of oozing. You can tune it out somewhat but switching to direct drive helped the most. The BMG extruder that comes with it is good quality and you could use it for direct drive but it is quite heavy and I would recommend converting it to Sailfin or superfly extruder.

- The stock firmware worked but I wanted to use Klipper anyway so I flashed it after a few days. I’m going to explain why in a different post.

There has been at least three different revisions of this printer:

- Revision 1 (the original) had belted Z steppers on a single driver (A4988). 2x TMC2208 for X and Y, and another A4988 for extruder. It also had badly designed belt path.

- Revision 2 was improved with independent Z axis running on 2x A4988, the extruder driver was also upgraded to TMC2208. It still had incorrect belt path.

- Revision 3 (also called 1.1) supposedly fixed the belt path. It also switched all drivers to TMC2225 but for some reason went back to belted Z. It also came with glass bed and revised bottom enclosure.

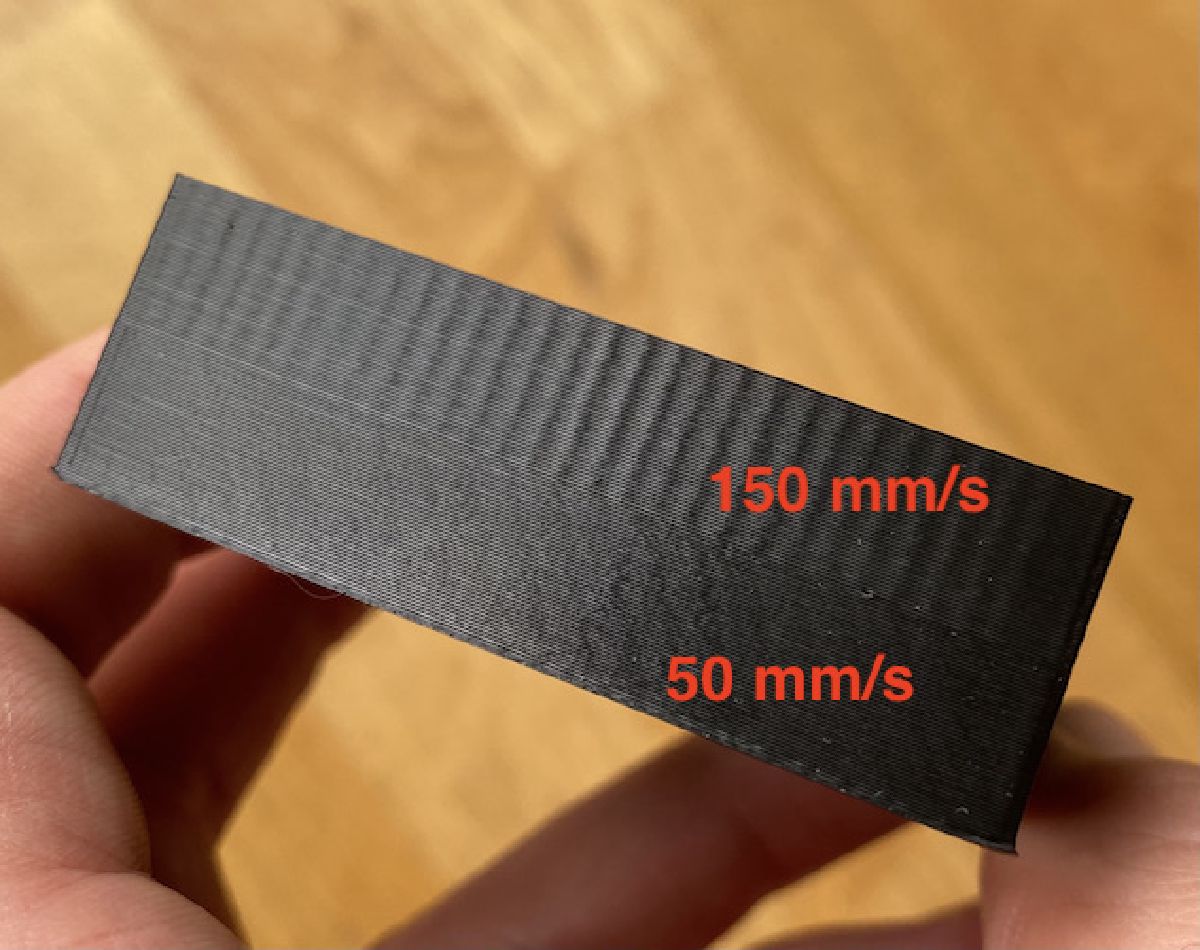

Revisions 2 and 3 are (was?) being shipped at the same time and I got the older one. Even though on this revision the belt path is not 100% parallel where it should be but it still produced dimensionally accurate prints. I read on the forums that the 1.1 doesn’t have this issue but I can’t confirm. All revisions have 6x toothed idlers and due to poor quality (?) at higher speeds they produce visible belt teeth pattern on the prints. I will try running with smooth idlers or I may have to re-design the belt path so it runs on the flat side. I will post an update when I figure this out.

What upgrades should you do?

I’m going to post a short guide for each upgrade I did to my Sapphire Plus but here’s the gist:

- Install Raspberry Pi and flash Klipper firmware. Adding Raspberry Pi to your printer is a better way to manage prints over WiFi than various addon modules (even when you get them to work they are slooow). Using Klipper firmware allows you to change configuration without reflashing firmware and enables unique features like pressure advance and resonance tuning.

- Enable UART communication with the stepper drivers. It will allow you to configure stepper current, enable StealthChop/SpreadCycle without physically adjusting the drivers.

- Install bed probe and enable bed tilt leveling because manual bed leveling gets boring pretty quick.

- Upgrade to direct drive extruder. I would recommend direct drive for everybody. It will improve print quality and allow to print flexible filaments. Choose the lightest setup you can get because the heavier the tool head the slower you will have to print.

- Get a higher flow hotend. Finally, to reach the speeds of 200-300mm/s you will need a better hotend. All metal V6 is a great affordable choice but to get the maximum get a high flow hotend like Dragon HF.

After all these upgrades the Sapphire Plus is comparable to a high end printer at around half the cost.

Was it a good choice?

Yes and no. I like tinkering and I didn’t mind fixing and modding it. I still think it’s a good value considering all the components you get even if you need to replace a few. However, I would not recommend it for a person who expects to get reliable prints out of the box and every single time. I recommend buying it here to get a decent buyer protection.

Pros

- Solid construction and CoreXY kinematics

- Linear rails for all axis

- Stable bed platform with dual Z axis

- Good value for money

Cons

- Poor assembly instructions

- Poor quality belts and pulleys

- Noisy fans

Update: The printer was originally called Sapphire Plus but later renamed to SP-5.